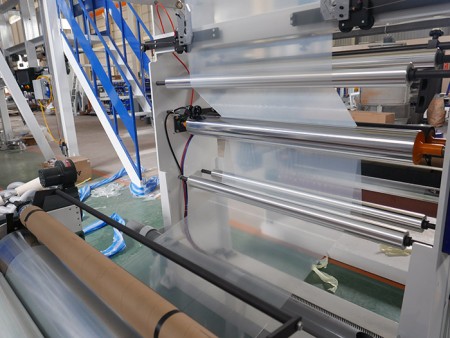

High-Speed Mono-layer Blown Film Machine

Model: ST

Monolayer blown film machine

Advanced screw design and groove feeder to get excellent material mixing, high output, and reliable production quality.

Unique die head and air ring to achieve stable bubble and better even thickness film and bag. Provides a good solution for T-shirt bag, shopping bag, agriculture, and many others.

Adjustable tower height.

Features

- Raw material be used: HDPE / LDPE / LLDPE / EVA.

- High efficient machine with low energy consumption but high output.

- High class gear box with enforced lubrication system and oil cooler.

- Good mixing performance from screw and barrel.

Optional Devices

- Auto-loader

- Single-layer dies & air rings

- A/A Two-layer dies & air rings

- Rotary die

- Manual screen changer

- I.B.C. (Internal Bubble Cooling)

- OBC

- Film thickness (gauge) control system

- Corona treater

- Embossing roller

- Double winder

- Load cell

- In-line flexographic printer

Specification

| Model | ST45 | ST55 | ST65 | ST75 |

|---|---|---|---|---|

| Applicable Material | HDPE / MDPE / LDPE / LLDPE / EVA / CACO3 / Recycled Material | |||

| Screw Dia. (mm) | Φ45 | Φ55 | Φ65 | Φ75 |

| Max. Film Width (mm) | 700 | 1000 | 1200 | 1500 |

| Max. Output | 75 kg/hr | 100 kg/hr | 160 kg/hr | 200 kg/hr |

| Screw L/D Ratio | 30:1 | 30:1 | 30:1 | 30:1 |

| Main Motor (w/ Inverter) | 30 HP | 40 HP | 60 HP | 75 HP |

* Specifications are subject to change without notice.

- Photo Gallery

- Movies

- Related Products

High-Speed Two-Head Mono-layer Blown Film Machine

Model: ST-TD

This two-head blown film machine line can produce 2 film rolls of the same width at the same time, and the production capacity is thus comparatively higher than models with only one die head. Thanks to the twin-head design, it not only occupies less space but also consumes less energy, which offers an economical solution for producing plastic bags of smaller width.

Mini Type Blown Film Machine

Model: MT (HMB)

Mini type blown film machine features a compact design, which is an economical choice for manufacturing general packaging products, such as T-shirt bags, shopping bags, bags on rolls, bottom seal bags, and many others.

General Type Blown Film Machine

Model: GB

Compared to Mini Type Model, this General Type Blown Film Machine is more expandable for various devices.

Heavy-Duty Blown Film Machine

Model: FB

Heavy-Duty Blown Film Machine has width 2000 ~ 4000mm, for general packing and agricultural Hutch.Heavy duty construction, take up tower.Automatic surface winder with uploading device.Swing type manual screen changer.

Heavy-Duty Blown Film Machine with Oscillating Haul-off Unit

Model: HR

Heavy-Duty Blown Film Machine with Oscillating Haul-off Unit features width available from 2000 ~ 4000mm, excellent for heavy-duty bags.Unique die head and air ring design to achieve stable bubble and better even thickness film and bag.Gear box uses high torque and enforced lubrication system.Automatic surface winder with uploading device.Oscillating haul-off.

Two-Color Co-Extrusion Blown Film Machine

Model: CT-DC, CT-DCTD

The Two-Color Co-Extrusion Blown Film Machine is equipped with two extruders. This A/B type blown film machine is capable of producing two-layer/two-color films.

AB and ABA Co-Extrusion Blown Film Machine

Model: CT-ML

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film.

Oscillating Tower ABC Three-layer Blown Film Machine

Model: RCT-ABC

The ABC three-layer co-extrusion machine is your ideal choice for producing high-end plastic products, such as shrink films, agricultural mulches, electrical insulation films, packaging films, medical packaging films, stretch hood films. The raw material formula for each layer can be customized respectively according to your requirements.The oscillating haul-off unit provides excellent film gauge randomization, ensuring the production of high-quality and wrinkle-free films. The oscillating haul-off unit is also rather durable, and its equipment lifespan is much longer than the rotary die.

PP Blown Film Machine

Model: PP

High Speed PP Blown Film Machine is suitable for producing PP bags and fims.

- File Download

Atlas Machinery Product Catalog Blown Fim Machine and Plastic Recycling Machine

Catalog of Blown Film Machine and Plastic Recycling Machine from Atlas