Thank you for visiting ATLAStw in Plast Eurasia & Plastivion Arabia

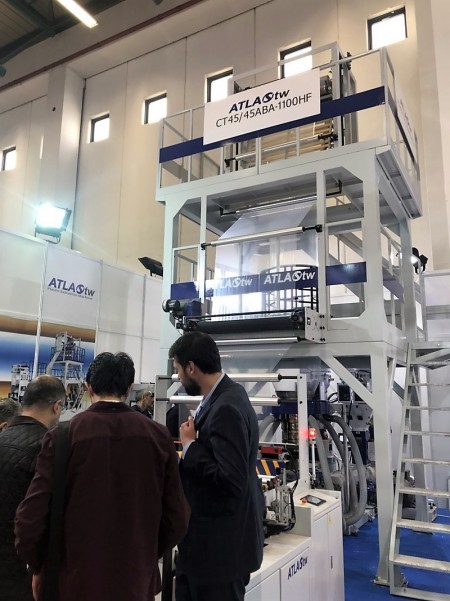

2017/12/25 Atlas MachineryIt is a great honor that ATLAStw attends Plast Eurasia İstanbul & Plastivision Arabia again this year. There are more than 300 visitors coming to our booth in Plast Eurasia and we demonstrate the CT-ML series ABA Three-layer blown film machine. In Plastivision Arabia in Sharjah, the WPF series Side Feeding Plastic Recycling Machine is displayed once more, and we want to show our appreciation to over 200 visitors paying attention to ATLAS' products.

If you have interests in the displayed machines, please click the tab below, or just contact us via the inquiry form below.

- Photo Gallery

- Display Product

AB and ABA Co-Extrusion Blown Film Machine

Model: CT-ML

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film.

Side Feeding Type Plastic Recycling Machine with Die Face Cutting

Model: WPF

Side feeding type plastic recycling and pelletizing machine is a special design from ATLAStw to solve the problem of uneven material feeding and clogged materials. Side feed plastic recycling machine installs a silo to store crushed materials and the side dosing screw quantitatively feeding the materials into the extruder. WPF series is our highly recommended model for not only its capability of processing both hard and soft plastics but its user-friendliness for one-person easy operation. In average, it only takes two hours for operating and maintenance training to manipulate the machine.